- Next Day Technology | Precise positioning system for underground personnel in coal mines to help coal mine safety production 2022-06-15

- Technology Empowerment丨Yiday Technology Coal Mine Electromechanical Equipment Whole Life Cycle Health Management and Control System 2022-06-10

- Next Day Technology丨What problems can the intelligent auxiliary transportation management platform for mines solve? 2022-05-20

- The next day technology KJ1461J coal mine underground personnel precise positioning system has passed the coal safety certification! 2022-05-17

- Recruitment | You have the ability, I have the position! 2022-05-16

- Next Day Technology丨Intelligent integrated management and control platform for mines, "icing on the cake" for the construction of smart mines 2022-04-25

- The next day technology mining vehicle auxiliary transportation management system makes auxiliary transportation safer! 2022-04-19

- The intelligent management and control system of underground traffic lights helps coal enterprises to create a more intelligent and efficient auxiliary transportation system! 2022-04-11

Next Day Technology | Precise positioning system for underground personnel in coal mines to help coal mine safety production

- Time of issue:2022-06-15

- Views:0

Next Day Technology | Precise positioning system for underground personnel in coal mines to help coal mine safety production

Coal production work is highly dangerous, and it is a compulsory course for coal mining enterprises to do a good job of "safety". Among them, the establishment of a positioning system and the use of technical means to improve the level of safety management are very important measures, which have been written into many industry documents.

"Coal mines must establish a system for checking the body in and out of the well and a system for checking personnel entering and leaving the well; it is necessary to master real-time information such as the number and location of underground personnel" - "Coal Mine Safety Regulations"

"Real-time collection of mine safety monitoring, personnel location monitoring, video surveillance and other data, and building a comprehensive mine safety production information system that connects users at all levels and roles" - "14th Five-Year Plan for Mine Safety Production (Draft for Comments)" )"

"Moving target precise positioning system: Using precise positioning technology, it can realize the precise positioning of underground people, vehicles and other targets, personnel status analysis, attendance, dispatch management, meet the full coverage requirements of complex underground tunnels, and have the function of trajectory data display and analysis." ——《Guidelines for Intelligent Construction of Coal Mines (2021 Edition)》

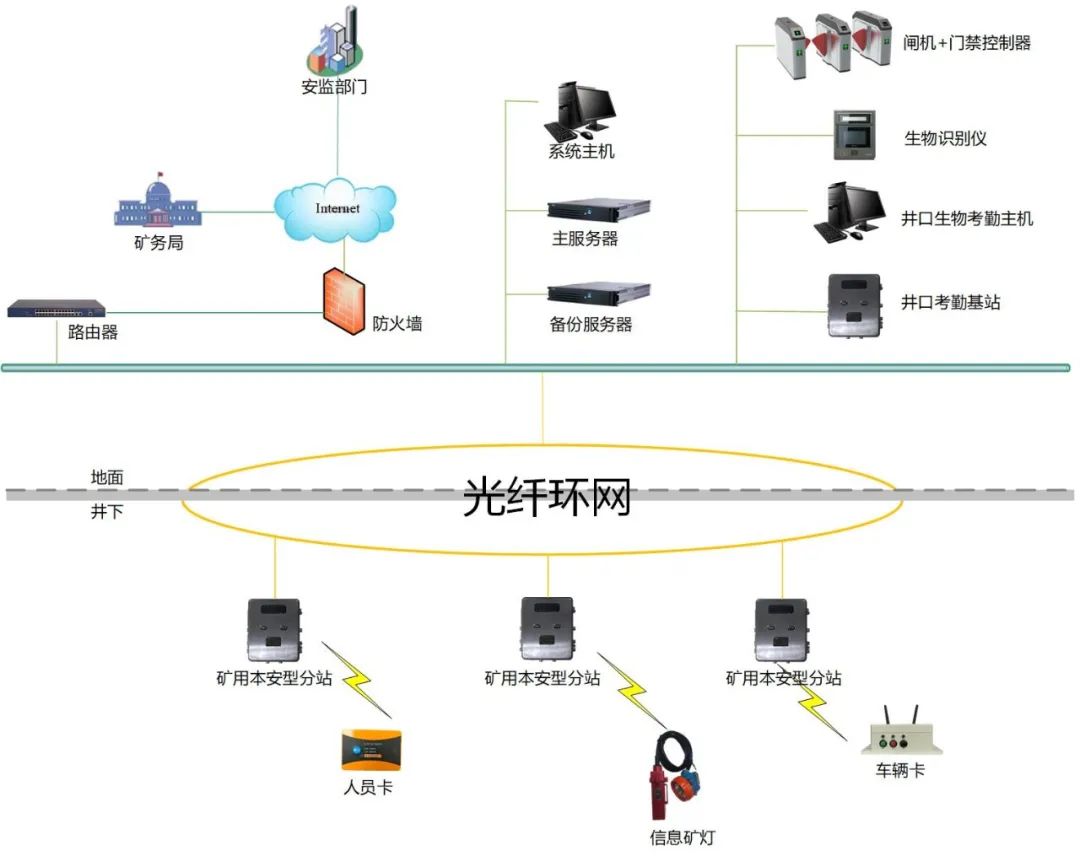

In order to better promote the intelligent construction of coal mines and improve the level of safe production in coal mines, Shenzhen Yiri Technology Co., Ltd. has launched a set of precise positioning system for underground personnel in coal mines (KJ1461J).

Coal mine underground personnel precise positioning system (KJ1461J)

Next Day Technology Coal Mine Underground Personnel Precise Positioning System (KJ1461J), based on UWB precise positioning technology, can realize ranging and direction judgment with a single base station, and the static positioning accuracy is not more than 0.3 meters. Dynamic monitoring of downhole targets, combined with the system GIS two-dimensional plane map or three-dimensional visual map to present the real-time position and trajectory playback of underground personnel. The system has personnel/vehicle precise positioning, personnel/vehicle entry and exit attendance, real-time and historical track viewing, distress alarm, emergency evacuation, overtime alarm, personnel limit alarm, shift plan management, vehicle speeding alarm, human-vehicle anti-collision warning, various types of Statistical reports, etc. Combined with traffic light equipment and wireless communication equipment, it can also expand the intelligent control of underground traffic lights and the intelligent dispatching function of underground vehicles.

System Features

High-precision positioning: using signal time-of-flight positioning to achieve high-precision positioning of 30cm;

Single base station precise positioning: a single base station can realize ranging and direction judgment. Compared with dual stations (card readers), the number of devices used is less and the layout is more flexible;

Single station coverage distance: coverage diameter ≥ 800 meters (visible distance);

Strong scalability: the base station can expand the wifi module to realize the function of wifi calling and data transmission;

Comprehensive functions: support precise positioning and management of people and vehicles, and can also expand functions such as intelligent control of traffic lights, intelligent management of auxiliary transportation (smart scheduling), etc.;

Simple networking and convenient construction: The base station of the system adopts a variety of networking methods such as optical fiber cascade and 485 bus, and different networking schemes can be selected according to different areas in the well.

Supporting software system

The personnel precise positioning system is based on the research and development of UWB precise positioning technology and GIS geographic information technology in coal mines. Realize efficient management of coal mine personnel, eliminate hidden dangers and ensure safe and efficient coal mine production.

Software system features

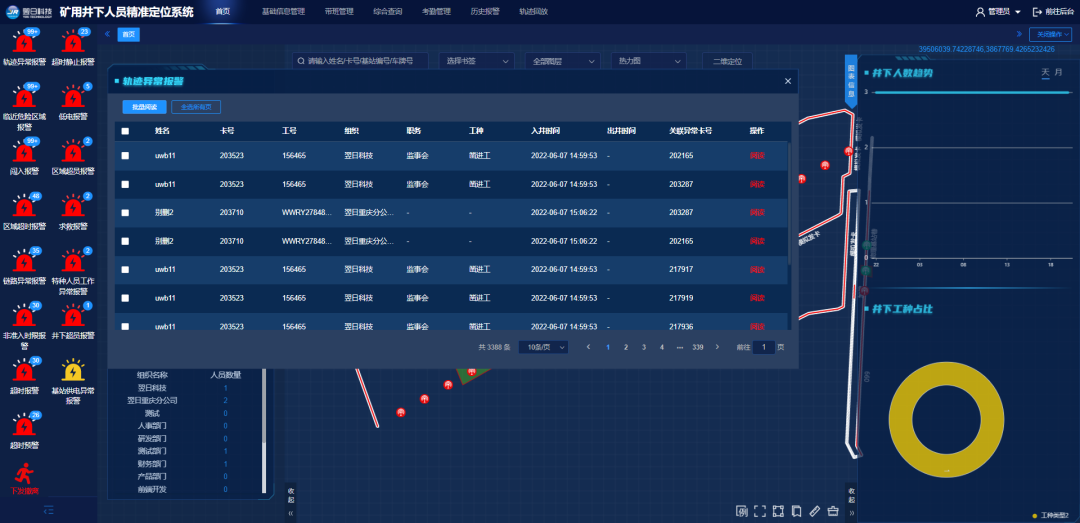

1. Real-time positioning monitoring - accurately reflect the precise location of underground operators and vehicles, and provide key data for personnel management and post-disaster rescue.

2. Real-time alarm - push 15 types of alarm information in real time, quickly grasp the operation conditions of the underground, and take corresponding rescue measures in time.

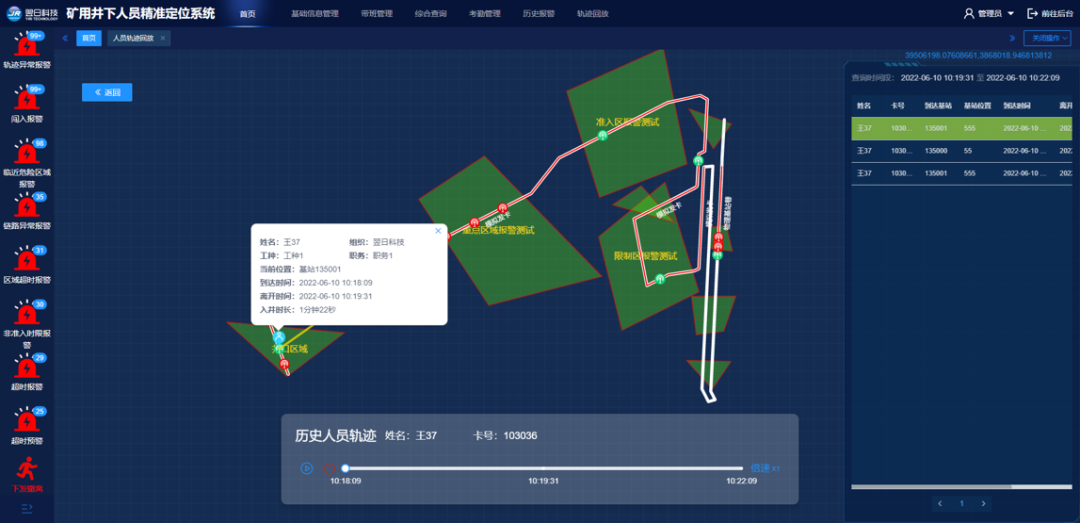

3. Track playback - record the movement track of the personnel, and play the track screen with animation. According to the input identification card number or personnel name, you can query the detailed information of the employee's movement trajectory on the day or within a certain period of time, and at the same time realize the playback of the trajectory map, and intuitively reproduce the employee's passing situation on the day.

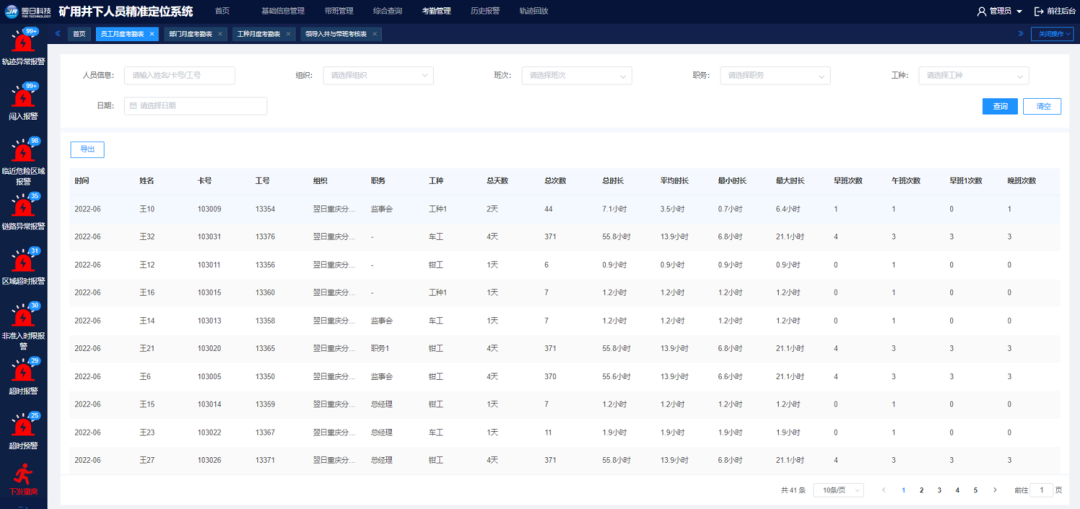

4. Attendance management - the system provides functions including monthly attendance of employees, monthly attendance of departments, monthly attendance of work types, leader entry into wells and inquiries about class assessment. It can query and count the time of each person and department going down in any shift and specified time period; count the going-down situation of various types of work; can separately count and assess the situation of leaders entering the well and leading the shift.

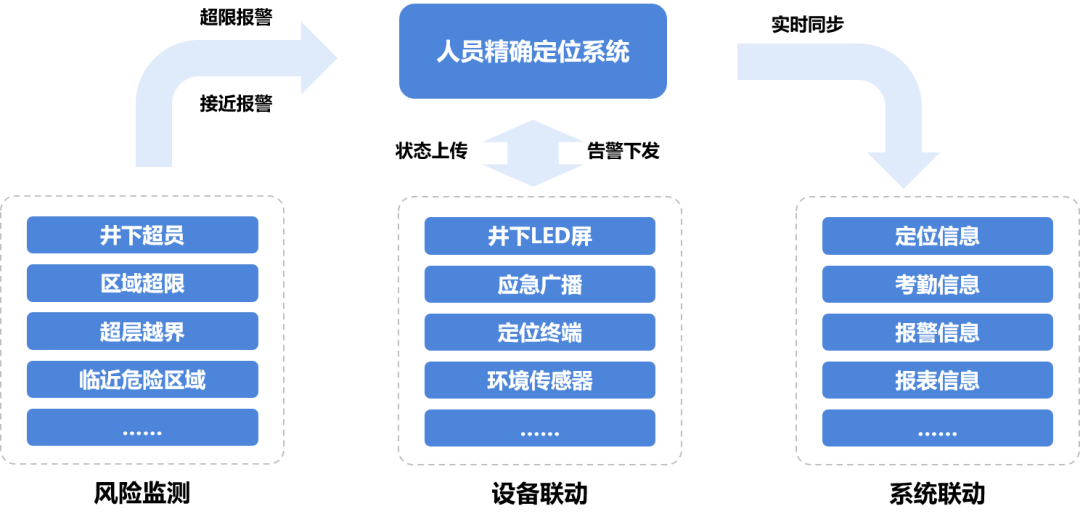

5. Safety monitoring and emergency handling - realize the functions of risk monitoring, equipment linkage, and system linkage.

6. 3D visualization - supports digital definition and 3D modeling of the composition, characteristics and functions of physical entities in main places such as underground tunnels, mining faces, pump rooms, substations, etc., and completes mapping in virtual space to realize production scenarios. 3D display and real-time monitoring of dynamic data.

Relevant Information

Service Hotline:

0755-86377030

© 2021 Shenzhen Yiri Technology Co., Ltd. . All rights reserved. Powered by www.300.cn 粤ICP备09071944号 SEO