- Next Day Technology | Precise positioning system for underground personnel in coal mines to help coal mine safety production 2022-06-15

- Technology Empowerment丨Yiday Technology Coal Mine Electromechanical Equipment Whole Life Cycle Health Management and Control System 2022-06-10

- Next Day Technology丨What problems can the intelligent auxiliary transportation management platform for mines solve? 2022-05-20

- The next day technology KJ1461J coal mine underground personnel precise positioning system has passed the coal safety certification! 2022-05-17

- Recruitment | You have the ability, I have the position! 2022-05-16

- Next Day Technology丨Intelligent integrated management and control platform for mines, "icing on the cake" for the construction of smart mines 2022-04-25

- The next day technology mining vehicle auxiliary transportation management system makes auxiliary transportation safer! 2022-04-19

- The intelligent management and control system of underground traffic lights helps coal enterprises to create a more intelligent and efficient auxiliary transportation system! 2022-04-11

Next Day Technology丨Intelligent integrated management and control platform for mines, "icing on the cake" for the construction of smart mines

- Time of issue:2022-04-25

- Views:0

Next Day Technology丨Intelligent integrated management and control platform for mines, "icing on the cake" for the construction of smart mines

In the process of promoting the intelligent construction of coal mines, the phenomenon of "digital divide" and "information isolated island" has appeared in many systems. The precious data generated by each system cannot be deeply utilized, and it is difficult to form a unified information resource. In the intelligent construction of coal mines, the main problems are as follows:

There are many information systems, and the same basic data is defined differently in different systems, which cannot guarantee the uniqueness of the same object code and the consistency of upstream and downstream management specifications.

The professional subsystems of "mining, excavation, machinery, transportation, communication, and safety" involved in coal mine safety production work alone, and cannot form an integrated management platform for the entire production process.

With the development of mobile informatization, more and more applications have begun to expand to the mobile terminal. However, at present, there is a lack of unified management. Each system is developed relatively independently. The entrance cannot be managed uniformly.

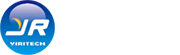

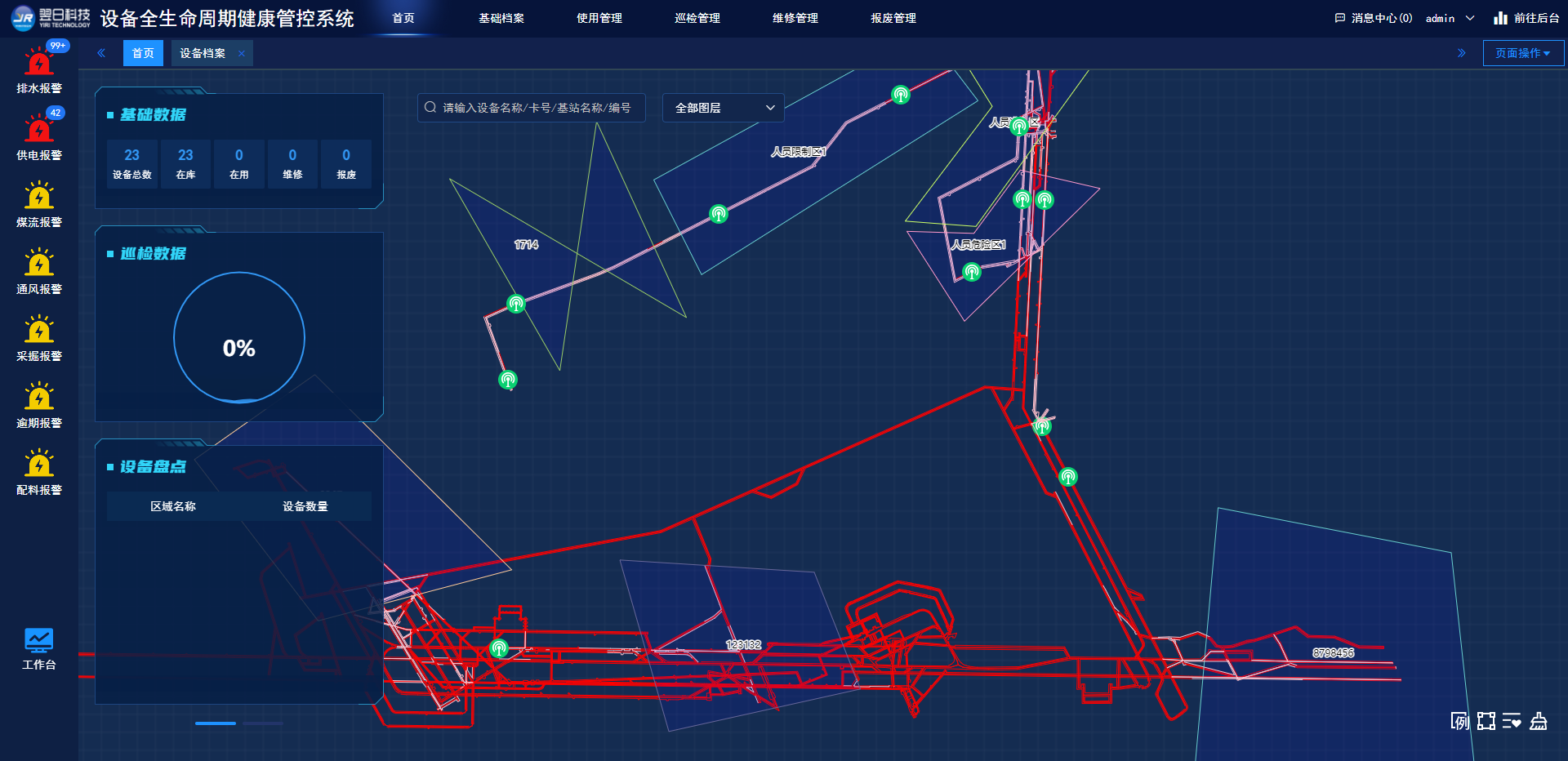

Based on this background, Yiri Technology independently developed an intelligent integrated management and control platform for mines. The coal mine's business modules such as human and vehicle positioning, equipment management, broadcast scheduling, monitoring and monitoring, production, sales and transportation are integrated into the mine's intelligent integrated management and control platform, the data is stored in a unified data warehouse, and a comprehensive display of the data is realized through a map. , and then realize a series of applications such as intelligent scheduling, intelligent production, intelligent safety, and intelligent decision-making in the process of intelligent management and control of coal mine safety production, promote less human and unmanned mining in mines, and achieve safe, efficient, and green operations.

Platform Features

1. Multi-source data fusion

The platform has unified data interface specification, unified data coding standard, unified data storage management, effective integration and data fusion of multi-source heterogeneous data.

2. Information linkage application

Predetermined system linkage rules to realize regional linkage, alarm linkage, system linkage and other functions.

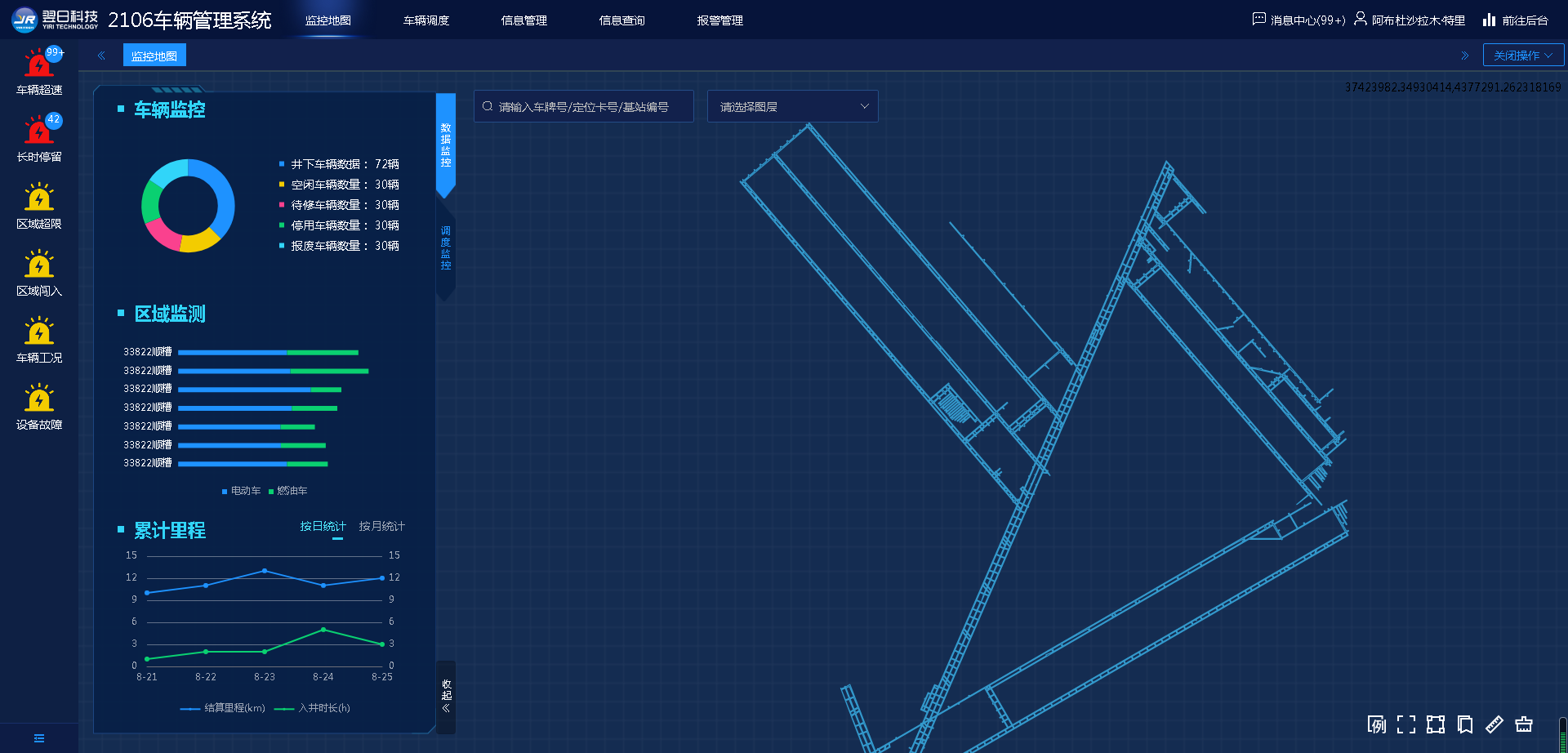

3. A GIS map

The mine information model is constructed through the organization of spatial geographic coordinates, and all personnel, equipment, sensors, environment and other data on the mine well and underground are defined in layers, and multi-layer 3D visualization is displayed on the GIS map. It has functions such as transparent information sharing, implementation tracking, trajectory playback, and multi-level zooming, which play an important basic supporting role in the management of underground personnel, equipment, and the environment.

4. Intelligent decision analysis

Establish data warehouses, knowledge bases, and use big data analysis technology to mine and analyze data to provide decision-making support for managers.

5. Customized development

According to the status quo of coal mines and application needs, on-demand customized function development services.

6. Mobile APP

The intelligent integrated management and control platform for mines is equipped with a mobile APP. The mobile APP has functions such as personnel positioning, vehicle management, route planning, alarm and early warning, equipment management, and voice and video communication.

3D visualization

It supports digital definition and 3D modeling of the composition, characteristics, and functions of physical entities in main places such as underground tunnels, mining faces, pump rooms, and substations, and completes mapping in virtual space to realize 3D display of production scenes and dynamic data. real-time monitoring.

Subsystem introduction

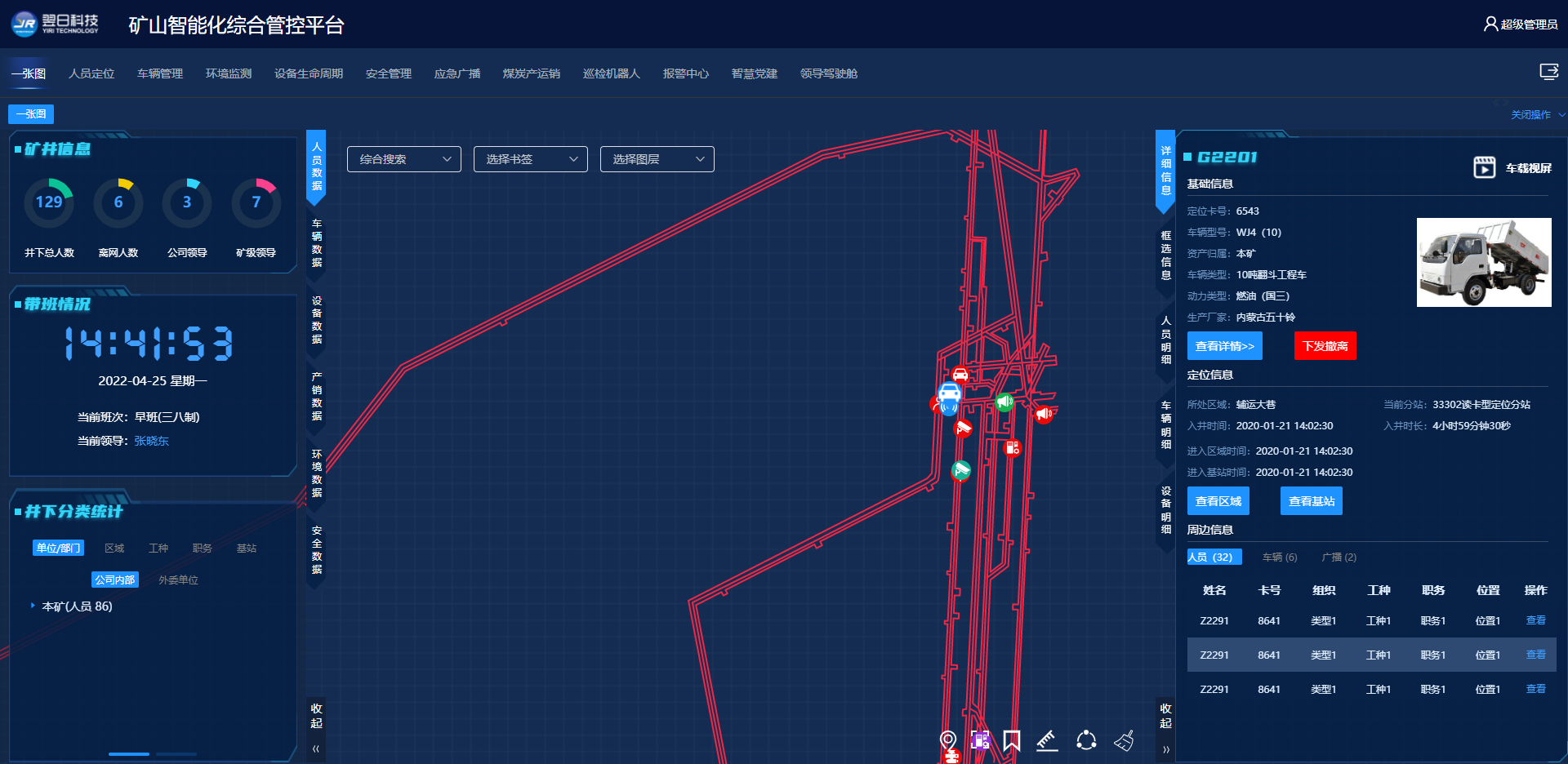

01 Underground vehicle management system

Based on UWB precise positioning technology, real-time positioning with static error <0.3m and dynamic error <10m is realized.

Core functions: real-time vehicle positioning, track playback, attendance, dispatching, and expense settlement.

02 Precise positioning system for underground personnel

Based on UWB precise positioning technology, real-time positioning with static error <0.3m and dynamic error <7.3m is realized.

Core functions: personnel real-time positioning, track playback, attendance, related alarms and evacuation.

03 Coal mine equipment life cycle health management and control system

Through the data collection, analysis and statistics of large-scale equipment, the equipment life cycle health management and control system realizes the whole life cycle closed-loop management of equipment selection, procurement plan, production and use, online inventory, monitoring and analysis, fault warning, inspection and maintenance, and scrapped regeneration.

Core functions: inventory based on equipment positioning; online process management for the entire life cycle of equipment; collection, storage, and reporting of major equipment perception data; fault warning based on equipment temperature and vibration data, and real-time monitoring of equipment health status.

04 Underground Robot Intelligent Inspection System

The underground robot intelligent inspection system is an autonomous power, integrated sensing technology, robotics and artificial intelligence analysis technology, with real-time power monitoring, feeding autonomous charging, data collection and analysis and other functions for the inspection of underground coal mines. During the movement, it can analyze the equipment failure points and the illegal operation behavior of personnel according to the video and infrared thermal images. The robot can last for 8 hours on a full charge, and the mileage can reach 12 kilometers (the default speed is 0.5m/s, according to the horizontal track).

Core functions: main transport belt inspection, deviation, tearing, coal pile, foreign body, idler stuck, etc.; substation, pump house inspection, instrument reading identification, personnel intrusion alarm, gas over-limit alarm.

Relevant Information

Service Hotline:

0755-86377030

© 2021 Shenzhen Yiri Technology Co., Ltd. . All rights reserved. Powered by www.300.cn 粤ICP备09071944号 SEO